Decoding Piping Isometric Symbols and Abbreviations

Decoding Piping Isometric Symbols and Abbreviations: Your Essential Guide

II JAY SHRI KRISHNA II

In our previous exploration, "Unlocking the Secrets of Piping Isometrics: A Beginner's Guide," we established the fundamental importance of these drawings as the language of pipe fabrication and installation. We learned that isometrics translate complex three-dimensional piping systems onto a two-dimensional plane, providing crucial instructions for bringing designs to life. Now, we delve deeper into the very grammar of this language: the symbols and abbreviations that populate these drawings.

|

Decoding Piping Isometric Symbols and Abbreviations |

Introduction:

To the untrained eye, an isometric might still appear as a collection of abstract lines and cryptic notations. However, understanding these visual cues is key to unlocking the wealth of information they contain. This essential guide will guide you through the most common symbols and abbreviations encountered in piping isometrics, transforming those seemingly random marks into clear and actionable instructions. Consider this your Rosetta Stone for deciphering the intricate details of piping layouts.

_______________________________________________________

Detailed Explanation of Symbols for Pipes:

The basic and most crucial element of any piping isometric is the representation of the pipes. While seemingly straightforward, even the way pipes are depicted can convey important information:

- Straight Runs: Typically shown as continuous lines drawn at the isometric angles (30 degrees from the horizontal). The continuous lines indicate or shows the straight portions of the piping.

- Bends (Elbows): Changes in direction are indicated by curved lines connecting straight pipe runs. You'll often find the bend's angle (e.g., 90°, 45°) clearly marked with the symbol. Different radii of bends might also be subtly indicated or specified with a note.

- Miters: Fabricated bends created by welding together beveled sections of pipe are sometimes represented differently from smooth bends, often with short, angled lines at the joint. The number of miters and the angle of each cut might be specified.

- Line Types: Line style variations provide different information. For instance, dashed lines might indicate underground piping or existing piping in a modification project, while thicker lines might highlight a specific pipe size or service. therefore, The drawing legend is crucial for understanding these distinctions.

Common Fitting Symbols:

Pipes are connected with their direction or diameter changed by fittings. Their symbols are crucial for interpreting the assembly on drawings:

- Elbows: As mentioned above, curves represent elbows. Various symbols might be used for long radius (LR) and short radius (SR) elbows and for different angles (like 90°, 45°, etc.). Some drawings might use a more stylized representation resembling the fitting itself.

- Tees: Typically shown as a "T" shape, indicating/showing a branch connection basically, at a 90-degree angle. Reducing tees (where the branch pipe has a smaller diameter) might be represented with unequal leg lengths or a specific abbreviation (e.g., RED TEE).

- Reducers: Used to connect pipes of different diameters. Concentric reducers (centered on the same axis) and eccentric reducers (offset axis) often have distinct symbols, typically converging or diverging lines.

- Couplings: Used to join two straight lengths of pipe. In drawings, they are commonly symbolized by two short parallel lines where pipes meet. Different types of couplings (e.g., threaded, socket weld) might have slightly different graphical representations or be indicated by abbreviations (e.g., THD CPLG, SOC CPLG).

- Flanges: Used for bolted connections, allowing for easier disassembly. They are often represented or symbolized by parallel lines perpendicular to the pipe, sometimes with small circles showing bolt holes. Different flange types (e.g., weld neck, slip-on) might be indicated by abbreviations (e.g., WN FLG, SO FLG).

- O'lets (Weldolet, Sockolet, Threadolet): Branch connection fittings that are welded or threaded onto a header pipe. Their symbols often resemble a small branch extending from the main pipe, with an indication of the connection type (e.g., WELDOLET, SOCOLET).

Valve Symbols:

Valves control the flow of fluids and have a variety of symbols to represent their different types and functions:

- Gate Valve: In piping isometrics, a gate valve is commonly depicted as a circle with a horizontal bar across it, frequently including an indication of the stem.

- Globe Valve: Similar to a gate valve but with a triangular shape inside the circle, representing the valve disc.

- Check Valve: Includes an arrow within the symbol indicating the direction of allowed flow. Different types of check valves (e.g., swing check, lift check) might have variations in the symbol.

- Ball Valve: Often represented by a diamond shape within a circle.

- Butterfly Valve: Typically shown as a circle with a line through the diameter and perpendicular "wings."

- Control Valve: Usually depicted with a more complex symbol, often including a diamond or square with additional notations indicating its actuating mechanism.

It's important to note that valve symbols can sometimes vary slightly between different drafting standards and companies, so always refer to the drawing legend.

Support and Anchor Symbols:

Supports and anchors play a critical role in keeping piping structurally sound and stable in each piping system. Their symbols indicate how the pipes are held and restrained:

- Pipe Shoe: Often represented by a rectangular block under the pipe.

- Hanger: Various symbols exist for different types of hangers, such as spring hangers (often with a coiled spring depicted), rigid hangers (simple vertical lines or brackets), and rod hangers.

- Anchor: Typically shown as a filled triangle or a more robust-looking support, indicating a fixed point that restricts movement in all directions.

- Guide: Allows axial movement of the pipe but restricts lateral movement, often represented by a rectangular shape with vertical lines on either side of the pipe.

The specific type of support is usually further defined by an accompanying tag number or note.

_______________________________________________________

Explanation of Line Types, Dimensioning Conventions, and Elevation References:

Beyond the component symbols, other graphical elements and notations are crucial for interpreting isometrics:

- Line Types: As mentioned earlier, different line styles can convey various meanings. A solid continuous line usually represents the main piping. Dashed lines might point to hidden lines, existing piping or tracing. Centerlines might be used for dimensioning reference. Always consult the drawing legend for clarification.

- Dimensioning Conventions: Dimensions on isometrics follow specific conventions. They are typically shown as linear distances parallel to the isometric axes. Extension lines extend from the points being dimensioned, and dimension lines with arrowheads indicate the measured distance. Center-to-center dimensions between fittings are common, as are end-to-end dimensions for spools. Take careful note of where the dimension lines originate and terminate.

- Elevation References: The vertical position of piping is very important. Elevations are often indicated using tags or notes (e.g., EL. 10000). These references usually relate to a specific datum or benchmark on the plant site. Sometimes, elevation changes are implied by the isometric projection itself, but critical elevations are always explicitly stated.

_______________________________________________________

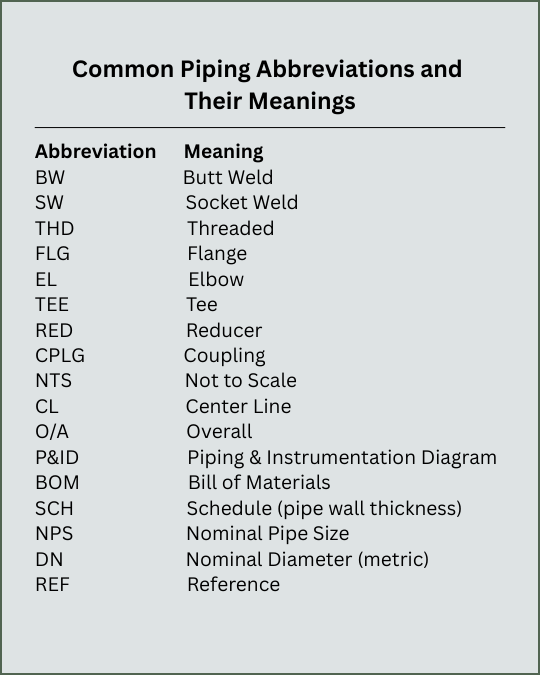

A Handy Reference Table of Common Symbols and Abbreviations:

While visual representations are helpful, a quick reference table for common abbreviations can significantly speed up the interpretation of isometric drawings. Here are a few examples:

|

Common Piping Abbreviations and Their Meanings |

This is just a small sample, and a comprehensive list would be much longer. Always refer to the specific project's drawing legend for a complete list of symbols and abbreviations used.

_______________________________________________________

Conclusion:

Decoding the symbols and abbreviations on a piping isometric drawing is akin to learning a new language. While it might seem daunting initially, with practice and the aid of resources like this essential guide and the drawing legend, you'll gain fluency in interpreting these vital documents. Understanding these visual and textual cues unlocks the detailed instructions necessary for accurate fabrication, efficient installation, and effective communication throughout the lifecycle of a piping system.

In our next post, we will build upon this knowledge by exploring the crucial aspect of dimensions and tolerances in piping isometrics, further refining your ability to read and understand these essential engineering drawings.

_______________________________________________________

🚀 For more insights, check out these related posts:

Unlocking Secrets Piping Isometrics: Beginner's Guide

Mastering Piping Isometric: Dimensions and Tolerances

Advanced Concepts in Piping Isometrics And Spooling Strategies

Checklist for Piping & Instrumentation Engineering Drawings Review

Piping Design Checklist for Accurate Engineering Drawings

Guidelines for Developing an Equipment Layout Drawing

Piping GA Drawing: A Comprehensive Guide Series - Part 1: Fundamentals

Piping Interview Preparation: Site Selection, Plot Plans & GA Drawings

Effect of Piperack Piping: Enhanced Overall Plant Performance

Equipment Layout: An Effective Industrial Arrangement

Please like, message and share if you feel all my blogs are beneficial, useful or helpful for you and for other also.

Thank you so much for following my blog…!! 🙏

See you all in the next coming blogs till then keep exploring piping field……!!

Have a great day today.... Keep smiling 😀 and God Bless You all…!!

To be continue……

Post a Comment